1. INTRODUCTION

1.1 GENERAL

Concrete is the world’s most versatile,

durable and reliable construction material. Large quantities of Portland cement

are required for concrete. The consumption of Ordinary Portland Cement (OPC)

causes pollution to the environment due to the emission of CO2. Geopolymer concrete was introduced to reduce environmental

pollution that causes by production of Portland cement.

In 1978, Professor Joseph Davidovits

introduced the development of mineral binders with an amorphous structure,

named geopolymers. Davidovits (1988; 1994) proposed that an alkaline liquid

could be used to react with the silicon (Si) and the aluminium (Al) in a source

material of geological origin or in by-product materials such as fly ash and

rice husk ash to produce binders. Because the chemical reaction that takes

place in this case is a polymerization process, he coined the term ‘Geopolymer’

to represent these binders. This was a class of solid materials, produced by

the reaction of an alumino silicate powder and an alkaline liquid. The initial

goal for the research done on these geopolymers was to find a more fire

resistant binder material due to the high amount of fires in Europe at that

time. This research led to the material being used as coatings for the fire

protection of cruise ships and thermal protect results in a low flexural

strength. Brittleness of both concrete types is compensated by conventional

steel reinforcement.

Geopolymer concrete is an innovative

construction material which shall be produced by the chemical action of

inorganic molecules. Otherwise geopolymer is an inorganic alumino- hydroxide

polymer synthesized from predominantly silicon (Si) and aluminium (Al)

materials of geological origin or byproduct materials such as fly ash. The term

Geopolymer was introduced to represent the mineral polymers resulting from

geochemistry. The process involves a chemical reaction under highly alkaline

conditions on Si-Al minerals, yielding polymeric Si-O-Al-O bonds in amorphous

form. Due to its high mechanical properties combined with substantial chemical

resistance (magnesium or sulphate attack), low shrinkage and creep and

environment friendly nature (very less amount of CO2 production in comparison

with OPC), it is a better construction material for future.

1.2 NECESSITIES OF GEOPOLYMER CONCRETE

This type of geopolymer concrete is starting

to revolutionize concrete. It is being used more in highway construction

projects and offshore applications. Construction is one of the world wide

growing fields. As per the present world statics, every year million tons of

cement are required. Ordinary Portland cement is commonly used in concrete.

While producing one ton of cement, approximately one ton of carbon di oxide

will be emitted to the atmosphere, which cause major problems in environment.

Also huge quantity of energy is also required for the production of cement.

Hence it is most essential to find an alternative binder. The Thermal Industry

produces a waste called fly ash which is simply dumped on the earth, occupies

large areas. The waste water from the Chemical Industries is discharged into

the ground which contaminates ground water. By producing Geopolymer Concrete

all the above mentioned issues shall be solved by rearranging them.

Waste Fly Ash from Thermal Industry + Waste

water from Chemical Refineries = Geo polymer concrete.

Since Geopolymer concrete doesn’t use any

cement, the production of cement shall be reduced and hence the pollution of

atmosphere by the emission of carbon di oxide shall also be minimized.

2. GEOPOLYMER CONCRETE

2.1 GEOPOLYMER THEORY

Geopolymerization is a geosynthesis, a

reaction that chemically integrates minerals. The exposure of aluminosilicate

materials such as fly ash, blast furnace slag, or thermally activated substances

to high-alkaline environments (hydroxides, silicates) gives rise to the

formation of a geopolymer. Geopolymers are characterized by a two- to

three-dimensional Si-O-Al structure.

Dissolution occurs immediately upon contact

between the alkaline solution and the pozzolanic material and allows for ionic

interface between species and the breaking of covalent bonds between silicon,

aluminium and oxygen atoms. The rate of dissolution is relevant to the amount

and composition of the ashes and the pH of the activating solution.

The polymerization process involves a substantially fast chemical reaction under alkaline conditions on Si-Al minerals, resulting in a three-dimensional polymeric chain and ring structure consisting of Si-O-Al-O bonds. The formed gel product contains alkaline cations which compensate for the deficit charges associated with the aluminium for silicon substitution. An intermediate, aluminium rich phase is first formed which then gives way to a more stable, silicon- rich three-dimensional gel product, which is dependent upon curing conditions and activator type.

2.2 GEOPOLYMER DEVELOPMENT

Geopolymer cements develop through a series

of several distinct reaction processes from initial pozzolanic activation to

final microstructure development. The major processes involved are dissolution

of the alumino silicate species within a highly basic, alkaline environment,

polymerization of the dissolved minerals into short-lived structural gel,

precipitation of formed hydration products similar to natural zeolites and

final hardening of the matrix by excess water exclusion and the growth of

crystalline structures. Figure 2.1 shows the overall polymerisation process in

alkali activated geopolymer concrete.

Fig.2.1

Geopolymer development

2.3 CONSTITUENTS OF GEOPOLYMER CONCRETE

2.3.1 Coarse Aggregate

Coarse aggregates used in case of cement

concrete can be used in case of Geopolymer concrete (GPC) also where the coarse

aggregate should conform to IS-383- 1970.

2.3.2 Fine Aggregate

In place of sand we can also use bottom ash

which can be a replacement of sand. Up to a level of 20% replacement of sand

gives a good compressive strength.

2.3.3 Admixtures

To improve the workability of fresh concrete,

a commercially available naphthaline based superplasticizer was used. Lignin

based first generation plasticizer shows better performance in terms of

workability over third generation superplasticizer. High range water reducing

naphthalene based super plasticiser, naphthalene sulphonate based superplasticizer

etc was also use.

2.3.3 Alkaline Activators

According to Prof. J. Davidovits the alkaline

liquid should be made prior to one day before mixing because at the time of

mixing of Na2SiO3 with NaOH

solution it generates a huge amount of heat and the polymerization takes place

by reacting with one another, which will act as a binder in the geopolymer

concrete. Common activators include NaOH, Na2SO4 , waterglass, Na2 CO3 , K2 CO3 , KOH, K2SO4 and cement clinker, the most utilized alkaline activators are a

mixture of sodium or potassium hydroxides (NaOH, KOH) and sodium waterglass

(nSiO2 Na2 O) or potassium

waterglass (nSiO2 K2 O).

Sodium Hydroxide (NaOH)

NaOH is also commonly used as an alkaline

activator in geopolymer production. Generally NaOH is available in market in

the form of pellets or flakes form with 96% to 98% purity where the cost of the

product depends on the purity of the material. The solution of NaOH was formed

by dissolving it in water with different molarity. It is recommended that the

NaOH solution should be made 24 hours before casting and should be used with 36

hours of mixing the pellets with water as after that it is converted to

semi-solid state.

The concentration and molarity of this

activating solution determines the resulting paste properties. While high NaOH

additions accelerate chemical dissolution, it depresses ettringite and CH

(carbon-hydrogen) formation during binder formation. Furthermore, higher

concentrations of NaOH promote higher strengths at early stages of reaction,

but the strength of aged materials were compromised due to excessive OH in

solution causing undesirable morphology and non-uniformity of the final

products. It is found that geopolymers activated with sodium hydroxide develop

greater crystallinity thus improving stability in aggressive environments of

sulphates and acids.

Potassium Hydroxide (KOH)

KOH has been found to produce high

compressive strengths and improved porosity in geopolymer cements. Since K+ is

more basic than other activating ions, it possesses a greater potential for

polymeric ionization in solution resulting in high reactivity of the prime

pozzolan, a denser final product and a matrix formation capable of achieving

increased compressive strength values. NaOH actually possesses a greater

capacity to liberate silicate and aluminate monomer.

Sodium Silicate (Na2SO3) and potassium silicate

Sodium silicate is also known as waterglass

which is available in the market in gel form. The ratio of SiO2 and Na2O in sodium silicate gel highly affects the

strength of geopolymer concrete. Mainly it is seen that a ratio ranging from 2

to 2.5 gives a satisfactory result.

Sodium or potassium silicates are

manufactured by using sand (SiO2) with sodium or potassium carbonate (Na2 CO3 or K2 CO3 ) at temperatures in excess of 1100 °C and dissolving the product

with high pressure steam into a semi-viscous liquid referred to as waterglass.

Waterglass is rarely used as an independent activating unit, because it does

not possess enough activation potential to initiate pozzolanic reaction alone.

It is commonly mixed with NaOH or KOH as a strengthening agent to enhance

alkalinity and increase overall specimen strength. The most common alkaline

liquid used in geopolymerization is a combination of sodium hydroxide or

potassium hydroxide and sodium silicate or potassium silicate.

2.3.6 Geopolymer

Geopolymers are formed by alkali-activating a

variety of materials including fly ash, blast furnace slag, thermally activated

clays etc. to produce a cement-like material. The three most common raw binders

used in geopolymerisation are slag, calcined clays (metakaolin) and coal fly

ash. The binder materials should contain high levels of aluminium (Al) and

silicon (Si) in amorphous form. The raw materials play a significant role in

the geopolymer reaction and affect the mechanical properties and microstructure

of the final geopolymeric products.

Generally, materials containing mostly

amorphous silica (SiO2) and alumina (Al2O3) are the source for geopolymer production.

Naturally available materials like kaolin , natural puzzolana and Malaysian

marine clay , treated minerals like metakaoline and waste materials like fly

ash ,Construction waste , red clay brick waste , fly ash and rice husk-bark

ash, fly ash and blast furnace slag etc can be used. Many different materials

have already been investigated and used as the binder in geopolymer concrete

mixes, including:

Ø Low calcium fly ash ( Class F fly-ash)

Ø High calcium fly ash (Class C fly-ash)

Ø Calcined kaolin or metakaolin

Ø Natural minerals containing Al and Si

Ø Silica fume

Ø Slag

Ø Red mud

Ø Albite

Metakaolin was widely used as the binder in

the early stages, but due to its flat shape it tends to have high water demand.

Fly ash particles have a rounder shape, ensuring more promising workability and

a low water demand.

3. GEOPOLYMER CATEGORIES

There are currently four different geopolymer

categories including:

Ø Slag based geopolymer

Ø Rock based geopolymer

Ø Fly ash based geopolymer

Ø Ferro-sialate based geopolymer

3.1 SLAG BASED GEOPOLYMER

The first geopolymer developed was a slag

based geopolymer in the 1980s. The reason for using this type of cement is due

to its the rapid strength gain as it can reach strengths of up to 20 MPa after

just 4 hours. Slag is a partially transparent material and a by-product in the

process of melting iron ore. It usually consists of a mixture of metal oxides

and silicon dioxide. It is also used in the cement and concrete industry. The

substitution of OPC with slag is one of the many benefits that it provides to

OPC concrete, reducing life cycle costs and improving the workability of the

fresh concrete, Easier finishability, higher compressive and flexural strength

and also the improved resistance to acid materials. The reactions of slag in

alkali activating systems and in cement blends are dominated by the small

particles. The particles that are above 20 µm usually react slowly, while

particles under 2 µm react completely within 24 hours. Thus, when slag is used

in geopolymerisation, careful control of the particle size distribution must be

ensured to control the strength of the binder.

Examples of slag used are; Iron blast-furnace

slag, Corex slag& Steel slag.

3.2 ROCK BASED GEOPOLYMER

To compose this type of geopolymer, a

fraction of the MK-750(“MK” is an abbreviation for metakaolin and the “750”

represents the temperature at which it was produced) in the slag based

geopolymer is replaced by natural rock forming materials such as feldspar and

quarts. This mixture yields a geopolymer with better properties and less CO2 emissions than that of the ordinary slag based geopolymer. The

components of rock based geopolymer cement is metakaolin MK-750, blast-furnace

slag, natural rock forming materials (calcined or non-calcined) and a user

friendly alkali silicate.

3.3 FLY ASH BASED GEOPOLYMER Fly ash is the waste material produced in blast furnace. Components of fly ash are amorphous composition (60%), quartz (20%), mullite (17%), maghemite (1.7%) and hematite (.9%).

3.3 FLY ASH BASED GEOPOLYMER Fly ash is the waste material produced in blast furnace. Components of fly ash are amorphous composition (60%), quartz (20%), mullite (17%), maghemite (1.7%) and hematite (.9%).

Fly ash is commonly used as a substitute for

OPC in concrete and the addition of it provides;

Ø Fly ash consists of spherical particles which improve the workability of the fresh OPC concrete. This enables one to reduce the amount of water in the mix which reduces the amount of bleeding of OPC concrete.

Ø Improves mechanical properties such as compressive strength, due to the water reduction and ensures a higher reactiveness and better “packing” of particles.

Ø Reduce the cost of the OPC concrete.

Ø Reduces the CO2 emissions and drying shrinkage.

Ø Smoother surface. .

Fig. 2.2

Graded fly ash

Fly ash can be divided in to two, type F fly

ash and type C fly ash. The type F fly ash can be again classified into two

Alkali-activated fly ash geopolymer and Fly ash/slag based geopolymer. most of

the globally available fly ash material is a low calcium by product obtained

from the burning of anthracite and bituminous coal.

Alkali-activated fly ash geopolymer

This kind of geopolymer usually requires heat

curing at 60 ºC to 80 ºC. It is also known as the alkali activation method. A

high concentration of sodium hydroxide solution is required to ensure an

adequate geopolymerisation process. The mixture consists of fly ash and a

user-hostile sodium hydroxide solution. The fly ash particles are embedded into

an aluminosilicate gel with a Si: Al ratio of 1 to 2.

Fly ash/slag based geopolymer

This kind of geopolymer is more user-friendly

and it hardens at room temperature. The mixture consists of a user-friendly

silicate, blast furnace slag and fly ash. The fly ash particles are embedded

into a geopolymer matrix with and Si: Al ratio of 2.

3.4 FERRO SIALATE BASED GEOPOLYMER

This type of geopolymer has the same

properties as rock based geopolymers but contains geological elements with high

iron oxide content, giving the geopolymer a red colour. Some of the aluminium

atoms in the matrix are substituted with iron ions to yield a poly

(Ferro-sialate) type geopolymer with the following formation: (Ca,K)-

(-Fe-O)-(-Si-O-Al-O-).

4. STUDY OF PROPERTIES OF GEOPOLYMER CONCRETE

4.1 STUDY OF FLY ASH BASED GEOPOLYMER CONCRETE

4.1.1Creep Test

Test Specimens

Test specimens for the creep test were

150x300 mm cylinders and eight cylinders were prepared for each test. Three

cylinders were used for measuring the creep, two companion cylinders measured

the drying shrinkage and the other three cylinders were used for the

compressive strength test.

Test Procedure

The three specimens for creep test were placed

in a specially-built creep testing frame with a hydraulic loading system.

Before the creep specimens were loaded, the 7th day compressive strength of

geopolymer concrete was determined by testing the three cylinders reserved for

the compressive strength test. The creep specimens were applied with a load

corresponding to 40 percent of the measured mean compressive strength of

concrete. This load was maintained as the sustained load throughout the

duration of the test. The strain values were measured and recorded immediately

before and after the loading. Strains experienced by the control shrinkage

specimens were measured at the same time as the strain measurements on creep

specimens. The strain values were measured and recorded at 2 hours, 6 hours,

and then every day for the first week, after loading. The measurements then

continued once a week until the fourth week. After that, the measurements were

done once in 2 weeks until the twelfth week and the once every four weeks until

one year. The creep tests were conducted in a laboratory room where the

temperature was maintained at about 23ºC, but the relative humidity could not

be controlled. The relative humidity varied between 40% and 60% during the

test.

Fig.4.1

creep test

In OPC concrete creep is higher than that of

geopolymer concrete and thus the geopolymer concrete specimens undergo low

creep.

4.1.2 Drying Shrinkage Test

Test specimen

75x75x285 mm prisms with gauge studs were

used for drying shrinkage test.

Test Procedure

The shrinkage strain measurements started on

the third day after casting the concrete. On the third day after casting, the

specimens were demoulded and the first measurement was taken. Horizontal length

comparator was used for length measurements. The next measurement was on the

fourth day of casting, considered as Day 1 for the drying shrinkage

measurements. The measurements then continued every day in the first week, once

a week until the fourth week, once in two weeks until the twelfth week, and then

once in four weeks until one year. During the drying shrinkage tests, the

specimens were kept in a laboratory room where the temperature was maintained

at approximately at 23ºC. The relative humidity of the room varied between 40%

and 60%.

Fig. 4.2

Horizontal Length Comparator with Drying Shrinkage Test Specimen

Geopolymer concrete specimens undergo low

drying shrinkage. The drying shrinkage of geopolymer concrete, cured at ambient

temperatures, shows shrinkage significantly higher than that of heat cured

geopolymer concrete. The excess water in the geopolymer concrete evaporates

during the heat curing process, eliminating almost any chance of drying

shrinkage. The drying shrinkage for geopolymer concrete cured at ambient

temperatures is similar compared to that of OPC concrete. Figure 4.3 shows the

drying shrinkage of heat cured and ambient curing specimens.

Fig.4.3

Drying shrinkage of heat cured and ambient cured specimens

4.1.3 Sulphate Resistance Test

Test Procedure

The test specimens were immersed in sulphate

solution on the 7th day after casting. Sodium sulphate (Na2 SO4) solution with 5% concentration was used as

the standard exposure solution for all tests. The specimens were immersed in

the sulphate solution in a container, the volume proportion of sulphate

solution to specimens was four to one. In order to maintain the concentration,

the solution was replaced every month.

Fig.4.4

Specimens Soaked in Sodium Sulphate Solution

4.1.4 Acid Resistance Test

Sulphuric acid is one type of acid solution

that is frequently used to simulate the acid attack in sewer pipe systems. In

such systems, sulphuric acid attack is a particular problem as it is generated

bacterially from hydrogen sulphide. To test the acid resistance of geopolymer

concrete, the specimens be exposed to sulphuric acid solution with a

concentration of pH = 1. To evaluate the acid resistance of fly ashbased

geopolymer concrete, the specimens were soaked in sulphuric acid solution with

selected concentrations ranging from 0.25% to 2% with the measured pH ranges

from about 0.9 to 2.1, up to one year of exposure. The test specimens were

immersed in sulphuric acid solution in a container; the ratio of the volume of

the acid solution to the volume of the specimens was 4. The solution was

stirred every week and replaced every month.

4.1.5 Compressive Strength

It has been confirmed that geopolymer

concrete can reach significantly high compressive strengths when cured either

by heat activation or at ambient temperatures. Heat activation is necessary to

accelerate the geopolymerisation process and therefore higher compressive

strengths will be achieved when heat activated, compared to ambient curing. The

addition of slag in the matrix improves the compressive strength of the

geopolymer concrete significantly when cured at ambient temperatures.

The test results plotted in Figure 4.6 show

that the 7th day compressive strength of ambient-cured geopolymer concrete and

the subsequent strength gain with respect to age depend on the ambient

temperature at the time of casting. The 7th day compressive strength of fly

ash-based geopolymer concrete increased as the average ambient temperature at

casting increased. Also, the compressive strength of ambientcured geopolymer

concrete significantly increased with the age.

Fig. 4.5

Compressive Strength of Geopolymer Concrete Cured in Ambient Condition

4.1.6 Modulus Of Elasticity And Poisson’s Ratio

Tests have been conducted on the

stress-strain relationship of low calcium fly ash based geopolymer concrete and

it showed similar results to that of OPC concrete. The stress-strain curve of

geopolymer concrete agrees well with the predictions that were originally

developed for OPC concrete. As for OPC concrete, the modulus of elasticity

increased with the increase of compressive strength. According to previous

research it is suggested that fly ash based geopolymer concrete, cured at

elevated temperatures, yields higher modulus of elasticity values compared to

fly ash/slag based geopolymer concrete that cures at ambient temperatures.The

Poisson’s ratio of the geopolymer concrete specimens, with compressive

strengths ranging between 40 MPa and 90 MPa, was similar to that of OPC

concrete. But the modulus of elasticity can be brought equal to that of OPC

concrete by selecting the appropriate aggregate content as well as the optimum

fine aggregate to total aggregate ratio.

Table 4.1

Young’s Modulus and Poisson’s Ratio

Static modulus of elasticity for various mixes is given as;

Table 4.2

static modulus of elasticity for various mixes.

Where; Ec = ∆σ/∆

∆σ and ∆ are the increase in stress and strain respectively.

∆σ and ∆ are the increase in stress and strain respectively.

For OPC, EC =5000√fck N\mm2.

For GPC, EC =4600√fck N\mm2.

The stress-strain curve of OPC&GPC for various mixes are given

by,

Fig.4.6

Stress-Strain curves for OPC & GPC

4.2 STUDY ON PROPERTIES OF GEOPOLYMER CONCRETE USING

GLASS FIBER.

4.2.1 Experimental Investigation

The experiment is conducted to find out the

parameters that influences the mixture proportions and the properties of low

calcium fly ash- based geo polymers concrete and as in the case of OPC the

aggregates occupied 75- 80 % of the total mass of concrete. In order to

minimize the effect of the properties of the aggregates on the properties of

fly ash based geo polymers concrete.

4.2.2 Preparations Of geopolymer Concrete

Sodium Hydroxide solution

Sodium Hydroxide pellets are taken and

dissolved in water at the rate of 16 molar concentrations. It is strongly

recommended that the sodium hydroxide solution must be prepared 24 hours prior

to use and also if it exceeds 36 hours it terminate to semi solid liquid state.

So the prepared solution should be used within this time.

Molarity Calculation

The solids must be dissolved in water to make

a solution with the required concentration. The Concentration of sodium

hydroxide solution can vary in different molar. The mass of NaOH solids in a

solution varies depending on the concentration of the solution. For instance,

NaOH solution with a concentration of 16 molar consists of 16 x 40 = 640grams

of NaOH solids per liter of water, were 40 is the molecular weight of NaOH.

Note that the mass of water is the major component on both the alkaline

solutions. The mass of NaOH solids was measured as 444 grams per Kg of NaOH

solution with Concentration of 16 molar.

Fiber Proportion

Glass fibre of 0.5%, 1%, 1.5% and 2% is used

here to find out the optimum dosage of glass fibre based on its compressive,

tensile and flexural test results. For M 25 grade conventional concrete and

geopolymer concrete the compressive strength, tensile strength and load

deflection test results are conducted. GPC values are higher than conventional

concrete higher concentration (in terms of molar) of sodium hydroxide solution

results in higher compressive strength of fly ash-based geopolymer concrete.

4.3 Compressive Strength

Compressive strength is one of the important

properties of concrete. Concrete cubes of size 150mmx150mmx150mm were cast with

Glass fibers. After 24 hours, the specimens were demoulded and subjected to

water curing. After 28 days of curing specimens were taken and allowed to dry

and tested in compressive strength testing machine.

Table 4.3 compressive strength (% fiber

added)

Fig.4.7 Compressive strength chart

Split tensile strength is indirect way of

finding the tensile strength of concrete by subjecting the cylinder to a

lateral compressive force. Cylinders of size 150mm diameter and 300mm long were

cast with Glass fibers. After 24 hours the specimen were demoulded and

subjected to water curing. After 28 days of curing of specimens were taken and

allowed to dry and tested in universal testing machine by placing the specimen

horizontal.

Split tensile strength, fsp = 2P/π bd

Where, P = Load applied to the specimen in N

b =

Breadth of the specimen in mm

d = Depth of the specimen in mm

Table 4.4

split tensile strength (% fiber added)

Fig.4.8

Split tensile strength chart

4.5 Flexural Strength

Ø Flexural strength of a concrete is a measure of its ability to resist bending. Flexural strength can be expressed in terms of ‘modulus of rupture’.

Ø Concrete specimens for flexural strength were cross sectional area of 150mm width with 150mm depth and length of 700mm concrete beam.

The specimen is subjected to bending, using

four point loading until it fails. The distance of the loading point is 150mm

and the supporting point (L) is 450mm.

The flexural strength of concrete = P x L

x 1000 / B x D

Where,

P - Maximum load applied to the specimen in

KN.

L - Length of the specimen in mm. B - Width

of the specimen in mm

D - Diameter of the specimen in mm.

Table 4.5

Flexural strength (% fiber added)

Fig.4.9

Flexural strength chart

Result Obtained

Ø Compressive strength of 1% glass fiber reinforced concrete has found to be 10% increase in strength, when compared to that of Conventional concrete.

Ø Split tensile strength of 1% glass fiber reinforced concrete has found to be 10% increase in strength, when compared to that of Conventional concrete.

Ø Flexural strength of 1% glass fiber reinforced concrete has found to be 20% increase in strength, when compared to that of Conventional concrete.

5. ADVANTAGES OF GEOPOLYMER CONCRETE

5.1 High Strength

It has a high compressive strength that

showed higher compressive strength than that of ordinary concrete.it also has

rapid strength gain and cures very quickly. Making it an excellent for quick

builds. Geopolymer concrete has high tensile strength.it is less brittle than

Portland concrete and can withstand more movement. it is not completely earth

quake proof, but does withstand the earth moving better than traditional

concrete.

5.2 Very Low Creep And Shrinkage

Shrinkage can cause severe and even dangerous

cracks in the concrete from the drying and heating of the concrete or even the

evaporation of water from the concrete. Geopolymer concrete does not hydrate;

it is not as permeable and will not experience significant shrinkage. The creep

of geopolymer concrete is very low. The tendency of the concrete become

permanently deformed due to the constant forces being applied against it is

known as creep in concrete.

5.3 Resistant To Heat And Cold

It has the ability to stay stable even at

temperature of more than 2200 degrees Fahrenheit. Excessive heat can reduce the

stability of concrete causing it to spall or have layers break off. Geopolymer

concrete does not experience spalling unless it reaches over 2200 degrees

Fahrenheit.As for old temperatures, it is resistant to freezing. The pores are

very small but water can still enter cured concrete. When temperature dip to

below freezing that water freezes and then expands this will cause cracks to

form. Geopolymer concrete will not freeze.

5.4 Chemical Resistance

It has a very strong chemical resistance.

Acids, toxic waste and salt water will not have an effect on geopolymer

concrete. Corrosion is not likely to occur with this concrete as it is with

traditional Portland concrete.

5.5 Environmental Benefits

The use of geopolymer concrete reduces the need of OPC, that’s why we have to reduce the environmental pollution that caused by the emission of CO2 during the production of OPC.

6. Geopolymer Concrete shall be used in repairs and rehabilitation works.

6. DISADVANTAGE OF GEOPOLYMER CONCRETE

6.1 Difficult To Create

Geopolymer concrete requires special handling

needs and is extremely difficult to create. It requires the use of chemicals,

such as sodium hydroxide, that can be harmful to humans.

6.2 Pre Mix Only

Geopolymer concrete is sold only as a

pre-cast or pre mix material due to the dangers associated with creating it.

6.3 Geopolymerization Process Is Sensitive

This field of study has been proven

inconclusive and extremely volatile. Uniformity is lacking.

7. APPLICATIONS OF GEOPOLYMER CONCRETE

Geopolymer mortars and concretes possess a

high potential for use in commercial applications due to their enhanced

durability, thermal and chemical

22 resistance properties, rapid development of mechanical strength, adherence to reinforcements aggregates and economic benefit as an industrial by-product material.

22 resistance properties, rapid development of mechanical strength, adherence to reinforcements aggregates and economic benefit as an industrial by-product material.

7.1 Concrete Pipes The use of geopolymer concretes for commercial sewer piping is a good option from the basis of their resistance to sulphates and acidic products. Sulphuric acid is generated in conventional sewer systems through the breakdown of hydrogen sulphide by aerobic bacteria in the system and is the main factor in corrosion and structural deterioration of the piping networks over time. Approximately 40 percent of the damage to PCC pipes can be attributed to corrosion by biogenous sulphuric acid attack as a result of long flow periods and insufficient ventilation of wastewater.

Fig. 7.1

Precast Geopolymer Concrete Pipes

7.2 Structural Elements

Geopolymer concrete is used for the casting

of both columns and beams. The load capacity of geopolymer columns is

influenced by load eccentricity, concrete compressive strength values and

longitudinal reinforcement ratios. Decreased eccentricity loading and reinforcement

ratio increases favour an increase in overall column load capacity.

Fig.7.2

Geopolymer Columns After Demoulding.

Fig.7.3 Geopolymer beam(10.8m ) craned into position.

7.3 Pavements Geopolymer concrete is used for the construction of heat resistant pavement due to its thermal capacity. Pozzolan-based geopolymer cements do not readily decompose when exposed to high temperatures and appear to be more structurally stable under such conditions than PCC. Geopolymer cements utilize more and store less water from solution during particle reaction, and therefore, prevent aged dry shrinkage and strength degradation due to rapid water loss under extreme heat.

Fig.7.4

Placing Of Pavement Using Geopolymer Concrete.

7.4 Retaining Wall

A total of over fifty 40 MPa geopolymer

precast panels were used a retaining wall for a private residence. The panels

were up to 6 metres long by 2.4 metres wide and were designed to retain earth

pressure of 3 metres.

Fig.7.5

Precast Geopolymer Retaining Walls For A Private Residence.

7.5 Other Applications

According to Davidovits (1988), geopolymeric

materials have a wide range of applications in the field of industries such as

in the automobile and aerospace, nonferrous foundries and metallurgy, civil

engineering and plastic industries. The type of application of geopolymeric

materials is determined by the chemical structure in terms of the atomic ratio

Si:Al in the polysialate. Davidovits (1999) classified the type of application

according to the Si:Al ratio as presented in Table 9.6 . A low ratio of Si:Al

of 1, 2, or 3 initiates a 3DNetwork that is very rigid, while Si:Al ratio

higher than 15 provides a polymeric character to the geopolymeric material.

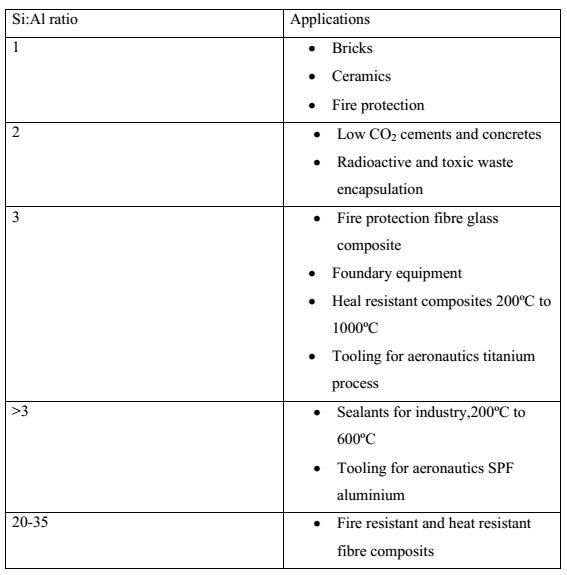

Table 7.1 Application of geopolymeric materials based on Si:Al atomic ratio Si:Al ratio

8. CONCLUSION

Geopolymer concrete is well known for its

promising mechanical properties, acid resistance and fire resistance and

therefore is a potential alternative construction material with comparable

properties to OPC concrete. The constituents of Geopolymer Concrete shall be

capable of being mixed with a relatively low alkali activating solution and

must be curable in a reasonable time under ambient conditions. Geopolymers emit

approximately 80% less CO2 than OPC during production, making it a more

environmental friendly building material. Like OPC concrete, geopolymer

concrete has a brittle failure. Alternatively, fibres can be added to improve

the ductility of concrete. The properties of geopolymer include high early

strength, low shrinkage, freeze-thaw resistance, sulphate resistance and

corrosion resistance. These high-alkali binders do not generate any

alkali-aggregate reaction. The geopolymer binder is a low CO2 cementious material. It does not depend on the Calcination of

limestone that generates CO2. This technology can save up to 80% of CO2 emissions caused by the cement and aggregate industries. Due to

the high early strength, Geopolymer Concrete shall be effectively used in the

precast industries, so that huge production is possible in short duration of

time.

REFERENCES

1.Ammar Motorwala, Vineet Shah, Ravishankar kammula, Praveena Nannapaneni, Prof. D.B. Ranjiwala (2013), Alkali Activated Fly-Ash

Based Geopolymer Concrete, International Journal of Emerging Technology and

Advanced Engineering, Volume 3, Issue1,159-166.

2. Kolli Ramujee, M. Potharaju (2014), Development of

Low Calcium Flyash Based Geopolymer Concrete, IACSIT International Journal of Engineering

and Technology, Volume 6, Issue 1.

3. M.I Abdul Aleem, P.D.Arumairaj(2012), Geopolymer

Concrete –A Review, International Journal of Engineering Sciences &

Emerging Technologies, Volume 1, Issue 2,118-122.

4. P. Vignesh, A.R.

Krishnaraja, N. Nandhini (2014), Study on Mechanical Properties of Geopolymer concrete using M-sand and Glass Fibers,

International Journal of Innovative Research in Science, Engineering and

Technology, Volume 3, Issue 2, 110-116.

5. Raijiwala D.B, Patil H.S (2011), Geopolymer Concrete:

A Concrete Of Next Decade, Journal of Engineering Research and Studies, Volume 2,

Issue 1,19-25.

6. S.E Wallah , B.V.Rangan (2006), Low Calcium Fly Ash

Based Geopolymer Concrete: Long Term Properties, Curtin University of Technology, Perth ,

Australia.

7. Tawatchai Tho-in, Vanchai Sata, Prinya chindaprasirt, Chai

Jaturapitakkul (2012), Pervious High Calcium Flyash Geopolymer Concrete,

ELSEVIER Construction And Building Material, Volume 25, Issue 1,366-371.

No comments:

Post a Comment