1. INTRODUCTION

A structure is designed for a specific period and its design life

varies depending on the nature of that structure. Now a day, deterioration in

concrete structures is a major challenge faced worldwide by the infrastructure

and bridge industries. The deterioration of structures is mainly due to

environmental effects , which includes corrosion of steel, gradual loss of

strength with aging, repeated high intensity loading, variation in temperature,

freeze-thaw cycles, contact with chemicals or saline water, and exposure to

ultra violet radiation. Since the complete replacement or reconstruction of

such structures will be cost effective, strengthening or retrofitting is an

effective way to strengthen the same. The most popular techniques for

strengthening of RC beams is the use of external epoxy-bonded steel plates

which increases the flexural strength of the beam. Even though steel bonding

technique is simple, cost-effective and efficient, it has the drawback that

steel will corroide and hence deterioration of bond occurs at the steel and

concrete interphase.

Other common strengthening technique involves construction of

steel jackets is quite effective but it increases the overall cross-sectional

dimensions, leading to increase in self weight of the structure and is labour

intensive. To eliminate these problems, steel plates were replaced by corrosive

resistant and light weight FRP composite plates. Also, such material could be

designed to meet specific requirements by adjusting placement of fibers. By

wrapping FRP sheets, retrofitting of concrete structure provide a more

economical and technically superior alternative to the traditional techniques

in many structures because it offers high strength, low weight, corrosion

resistance, high fatigue resistance, easy and rapid installation and minimal

change in structural geometry. FRP systems can also be used in areas with

limited access where traditional techniques would be impractical. Successful

retrofitting of concrete structures with FRP needs a thorough knowledge on the

subject and available user friendly technologies and unique guidelines.

Beams are the critical member which is subjected to bending,

torsion and shear in all type of structures. Similarly, columns are also

important elements subjected to axial load combined with or without bending.

Therefore, extensive research works are being carried out all over the world on

retrofitting of these concrete members with externally bonded FRP composites.

And several studies were conducted on retrofitting beams with carbon fibre

reinforced polymer (CFRP) or glass fibre reinforced polymer (GFRP) composites

in order to study the enhancement of strength and ductility, durability, effect

of confinement, preparation of design guidelines and experimental investigation

of these members.

2. FIBRE REINFORCED POLYMER COMPOSITE

Polymer composites are multi-phase materials and are produced by

combining polymer matrix with fillers and reinforcing fibers to produce a bulk

material with properties better than those of individual base materials. The

matrix can be thermoplastics like polypropylene, polyethylene, polystyrene, PVC

etc. or thermosetting like polyester, vinyl ester, and epoxy resins etc.

Fillers are often used in these composite in order to bulk the material, to

reduce cost, to lower bulk density or to produce aesthetic features. Fibers are

used in order to reinforce the polymer and improve its mechanical properties

such as stiffness and strength. High strength fibers of glass, aramid and

carbon are used as primary means of carrying load, while the polymer matrix

protects the fibers and bind them into a cohesive structural unit. These are

commonly called fiber-reinforced polymer composite materials (FRPs). Onwards

1960s, advanced composite material is found to have expanded uses in aerospace,

marine and automobile engineering due to their engineering properties including

specific strength and stiffness, lower density, high fatigue endurance, high

damping and low thermal coefficient in fiber direction. Recently, civil engineers

and construction engineer begun to realize the potential of these composite

material as strengthening material for many problems associated with the

deterioration of infrastructures. And also its use in construction field is

increased over the last decade. Since there is a continuous drop in the cost of

these materials, these being considered as a replacement to the conventional

steel in reinforced concrete structures. First application of these materials

composite is in the form of rebars and structural shapes. Later, FRP laminates

were used for strengthening of concrete bridge girders by bonding them to

tension face of girder as well as retrofitting of concrete columns. Now they

are available in the form of rods, grids, sheets and winding strands.

2.1 HISTORY OF FRP COMPOSITE

Bakelite was the first fibre-reinforced plastic. Dr. Baekeland

first produced a soluble phenol-formaldehyde shellac called “Novolak”, then

turned to developing a binder for asbestos which, at that time was moulded with

rubber. By controlling the pressure and temperature applied to phenol and

formaldehyde, in 1905, he produce the first synthetic plastic Bakelite.

The development of fibre-reinforced plastic for commercial use was

being extensively researched in the 1930s.a suitable resin for combining the

“fiberglass” with a plastic to produce a composite material was developed in

1936 by du Pont. With the combination of fiberglass and resin, the air content

of the material was replaced by plastic. This reduced the insulation properties

to values typical of the plastic, but now for the first time the composite

showed great strength and behaves as structural and building materials. Carbon

fibre production began in the late 1950s and was used in British industry

begins in the early 1960s. Aramid fibers were being produced around this time

also, and are appearing first under the trade name Nomex by du Pont. Today,

each of these fibers is used widely in industry for any applications that

require plastics with specific strength or elastic qualities. Now, these three

fibers continue to be the important categories of fibre used in FRPs.

3. COMPONENTS OF FRP COMPOSITES

An FRP is a specific type of two- component composite material

consists of high strength fibers embedded in a polymer matrix. The physical

properties and mechanical properties of this composite are mainly controlled by

the properties of its materials and the micro-structural configuration. The

fibers of the composite are mainly responsible for strength and the stiffness

properties, but the polymeric matrix contributes to the load transfer and

provides environmental protection. In addition to these fillers are used in the

FRP composite to reduce cost and sometimes to improve performance, imparting

benefits as shrinkage control, surface smoothness and crack resistance.

Additives and modifiers ingredients can expand the usefulness of polymeric

matrix, enhance their process ability or extend composite durability.

The reinforcing of low modulus polymeric matrix with high strength

and modulus fibers utilizes the viscoelastic displacement of the matrix under

stress to transfer the loads to the fiber, which results in a high strength and

high modulus composite material. The aim of this combination is to produce a

two phase material in which the primary phase, that determines stiffness, is in

the form of fibers and is well disperse and bonded and protected by a weak

secondary phase, the polymeric matrix. FRP composites are anisotropic.

Therefore they are directional, means that the best mechanical properties are

in the direction of the fibre placement.

3.1 REINFORCING FIBERS

The properties of FRP composite such as strength and stiffness

depends on the fibers provided. Because the fibers used in most structural FRP

composite are continuous and are oriented in specific directions. According to

Halliwell, the functional requirements of fibers in a composite are:

a) High modulus of elasticity to give stiffness.

b) High ultimate strength

c) Low variation of strength between individual fibers

d) Stability during handling

e) Uniform diameter

The fibers can

be used in different ways according to which the performance of the composite

changes.

· The highest performance in terms of strength and stiffness in one direction comes from unidirectional composites, when the fibers are parallel and gives their maximum possible performance in this single direction.

· By arranging this fiber in a weave or mat form, the strength can be gained in more directions, although the limit strength is reduced.

· By chopping the fibers into short lengths and arranging them randomly, equal strength is achieved in all directions. This is generally the cheapest technique, used for the least structurally demanding cases.

In civil

engineering mainly three types of fibers dominate; these are carbon, glass, and

aramid fibers and the composite is often named by reinforcing fiber. They have

different properties. All the fibers have generally higher stress capacity than

ordinary steel and have linear elastic property until failure. The most

important properties that differ between the fiber types are stiffness and

tensile strain. The mechanical properties of different types of reinforcing

fibers are shown in the table 3.1 below.

Table 3.1. Properties of different reinforcing fibers of FRP composites

The stress strain graph of all fibers is shown

in the figure 3.1 in comparison with the ordinary steel bars and steel tendons.

Figure 3.1. Properties of different fibers and typical reinforcing steel.

3.1.1.GLASS FIBER

"E" glass produced fibers are considered the predominant

reinforcement for polymer matrix composites due to their high electrical

insulating properties, low susceptibility to moisture and high mechanical

properties. Glass fibers used for

reinforcing composites generally range in diameter from 9 to 23 microns. Fibers are drawn at high speeds, approaching 200 miles per hour, through small holes in electrically heated bushings. These bushings form the individual filaments. The filaments are gathered into groups or bundles called "strands." The filaments are attenuated from the bushing, water and air cooled, and then coated with a proprietary chemical binder or sizing to protect the filaments and enhance the composite laminate properties. The sizing also determines the processing characteristics of the glass fiber and the conditions at the fiber-matrix interface in the composite.

reinforcing composites generally range in diameter from 9 to 23 microns. Fibers are drawn at high speeds, approaching 200 miles per hour, through small holes in electrically heated bushings. These bushings form the individual filaments. The filaments are gathered into groups or bundles called "strands." The filaments are attenuated from the bushing, water and air cooled, and then coated with a proprietary chemical binder or sizing to protect the filaments and enhance the composite laminate properties. The sizing also determines the processing characteristics of the glass fiber and the conditions at the fiber-matrix interface in the composite.

Glass is generally a good impact resistant fiber but weighs more

than carbon or aramid. Glass fibers have excellent characteristics, equal to or

better than steel in certain forms. The lower modulus requires special design

treatment where stiffness is critical. Composites made from this material

exhibit very good electrical and thermal insulation properties. Glass fibers

are also transparent to radio frequency radiation and are used in radar antenna

applications.

3.1.2. CARBON FIBER

Carbon fiber is created using poly acryl nitrile (PAN), pitch or

rayon fiber . PAN based fibers have good strength and modulus value and also

excellent compression strength. Carbon fibers are more expansive than glass

fibers. However, carbon fiber offers excellent combination of strength, low

weight and high modulus. The tensile strength of carbon fiber is equal to glass

while its modulus is about three to four times higher than glass. Carbon fibers

are supplied in a number of different forms, from continuous filament to

chopped fibers and mats. The highest strength and modulus are obtained by using

unidirectional continuous reinforcement. Twist-free tows of continuous filament

carbon contain 1,000 to 75,000 individual filaments, which can be woven or

knitted into woven roving and hybrid fabrics with glass fibers and aramid

fibers.

Carbon fiber composite are more brittle than glass or aramid. They

can cause galvanic corrosion when used next to metals. Barrier material like

glass and resin is used in order to prevent this corrosion.

3.1.3. ARAMID FIBER

Aramid fiber is an aromatic polyamid that is a man-made organic

fiber for composite reinforcement. Aramid fibers offer good mechanical

properties at a low density with the added advantage of toughness or

damage/impact resistance. They are characterized as having reasonably high

tensile strength, a medium modulus, and a very low density as compared to glass

and carbon. The tensile strength of aramid fibers are higher than glass fibers

and the modulus is about fifty percent higher than glass. These fibers increase

the impact resistance of composites and provide products with higher tensile

strengths. Aramid fibers are insulators of both electricity and heat. They are

resistant to organic solvents, fuels and lubricants. Aramid composites are not

as good in compressive strength as glass or carbon composites. Dry aramid

fibers are tough and have been used as cables or ropes, and frequently used in

ballistic applications.

The table 3.2 below shows the comparison of mechanical properties

between common strengthening materials and carbon fiber.

Table 3.2. Mechanical properties of different strengthening material and carbon fiber.

3.2. MATRIX

The matrix is

the binder of the FRP and place many important functions as follows:

· To bind the fibers together

· To protect the fiber from abrasion and environmental degradation

· To separate and disperse fibers within the composite

· To transfer force between the individual fibers

· To be chemically and thermally compactable with fiber

· To bind the fibers together

· To protect the fiber from abrasion and environmental degradation

· To separate and disperse fibers within the composite

· To transfer force between the individual fibers

· To be chemically and thermally compactable with fiber

According to Hollaway and Head (Elesvier 2001), the requirements

for a good FRP matrix are the following:

i. Wet out the fiber and cure satisfactory in the required

conditions

ii. Bind together the fiber and protect their surface from abrasion

and environmental ageing

iii. Disperse the fiber and separate them in order to avoid any

catastrophic propagation of cracks

iv. Transfer stresses to the fibers efficiently v. Be chemically

and thermally compatible with fibers

vi. Have appropriate fire resistance and limit smoke propagation

vii. Provide good aesthetic finish

There are mainly two types of polymer which determine the method

of manufacturing and the properties of the composite: (a) thermoplastic and (b)

thermosetting.

3.2.1. THERMOPLASTIC MATRIX

Thermoplastics are polymers composed of long-chain molecules that

are held together by relatively weak Van der Waals forces. But that have

extremely strong bonds within individual molecules. These polymers can be

amorphous, which implies a random structure with a high concentration of

entanglement, or crystalline, with a high degree of molecular order. The

molecules in this material can be slide over one another at high temperature,

so these materials can be repeatedly softened and hardened by heating and cooling

without significant change in their molecular structure. The semi-crystalline

polypropylene and nylon are especially popular as matrices.

3.2.2. THERMOSETTING MATRIX

3.2.2. THERMOSETTING MATRIX

Thermosetting polymers are also long-chain molecules built from

monomers, but for these materials the molecular chains are cross-linked through

primary chemical bonds. Thus, thermosets cannot be reversibly softened and will

deteriorate irreversibly at elevated temperature. These are usually made from

liquid or semi-solid precursors. These polymers generally have good thermal

stability at service temperatures, good chemical resistance, and display low

creep and relaxation properties in comparison with most thermoplastics. Since

it is difficult to reversibly soften thermosets, FRP components made from

thermosets matrices must be bent or formed during the manufacturing process.

This may become a problem in some specific application.

Three specific types of thermosetting resins are commonly used in

the manufacture of infrastructure composites: polyester resin, epoxy resin and

vinyl esters resin.

i. Polyester resin: They are the mostly used polymers in the

manufacture of FRP components for infrastructure applications due to their

relatively low cost and ease of processing. Numerous specific types of

polyesters are available for use, with varying degrees of thermal and chemical

stability, moisture absorption, and shrinkage during curing.

ii. Epoxy resin: Epoxies are often used in wet lay-up applications

of FRP plates and sheets because of their ability to cure well at room

temperature and owing to their outstanding adhesion (bonding) characteristics.

Epoxies have high strength, good dimensional stability, relatively good

high-temperature properties, strong resistance to chemicals (except acids), and

superior toughness. Epoxies, however, cost significant more than polyesters or

vinyl esters.

iii. Vinyl ester resin: Vinyl esters have similar mechanical and

in-service properties to those of the epoxy resins and equivalent processing

techniques to those of the unsaturated polyesters. Vinyl esters are resistant

to strong acids and alkalis, which is one reason that they are commonly used in

the manufacture of FRP reinforcing bars for concrete (the environment inside

concrete is highly alkaline). They also offer reduced moisture absorption and

shrinkage as compared with polyesters. Vinyl esters cost slightly more than

polyester.

3.3. FILLER

Fillers are inorganic materials added to the composite in order

reduce cost and also to impart performance improvements that might not

otherwise be achieved by the reinforcement and resins alone. They can improve

mechanical properties including fire and smoke performance by reducing organic

content in composite laminates. Also the important properties such as water

resistance, weathering, surface smoothness, stiffness, dimensional stability

and temperature resistance, can all be improved through the proper use of

fillers. There are a number of inorganic materials which can be used as

fillers, which includes calcium carbonate, kaolin (hydrous aluminum silicate),

alumina trihydrate, calcium sulphate.

3.4. ADDITIVES AND MODIFIERS

Additives are used in composites to modify materials properties

and tailor the

laminate’s performance. Although, these materials are generally used in relatively low quantity by weight compared to resins, reinforcements and fillers, they perform critical functions. Additives and modifier ingredients expand the usefulness of polymers, enhance their processibility or extend product durability. Catalyst, promoters, inhibitors etc. are the ingredients added as additives and modifiers.

laminate’s performance. Although, these materials are generally used in relatively low quantity by weight compared to resins, reinforcements and fillers, they perform critical functions. Additives and modifier ingredients expand the usefulness of polymers, enhance their processibility or extend product durability. Catalyst, promoters, inhibitors etc. are the ingredients added as additives and modifiers.

4. FABRICATION OF FRP COMPOSITES

There is a wide variety of

techniques by which FRP composites can be fabricated, even though there are

differences between the techniques available for thermosetting and

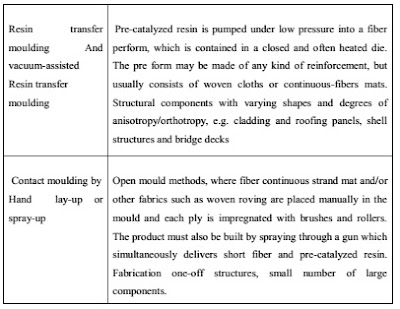

thermoplastics, due to their intrinsic properties. The table 4.1 shows the

commonly used process for fabrication of FRP composites applied in civil

engineering, their principle and typical application.

Table.4.1. Fabrication process of FRP composites

5. TYPES OF FIBER REINFORCED POLYMER

5.1. GLASS FIBER REINFORCED POLYMER

Glass fibers are basically made by mixing silica sand , limestone,

folic acid and other minor ingredients. The mix is heated until it melts about

12600C. The molten glass is then allowed to flow through fine holes in a

platinum plate. The glass strands are cooled, gathered and wound. The fibers

are drawn to increase the directional strength. The fibers are then woven into

various forms for the use in composites.

Based on aluminium lime

borosilicate composition glass produced fibers are considered the predominant

reinforcement for the polymer matrix composites due to their high electrical

insulating properties, low susceptibility to moisture and high mechanical

properties. Glass fibres have excellent characteristics equal to or better than

steel in certain forms. Glass is generally a good impact resistant fibre but

weighs more than carbon or aramid.

Figure 5.1. Glass fiber reinforced polymer sheet

5.2. CARBON FIBER REINFORCED POLYMER

Carbon fibers have a high modulus of elasticity, 200-800GPa. The

ultimate elongation is 0.3-2.5 % where the lower elongation corresponds to the

higher stiffness and vice versa. Carbon fibers donot absorb water and are

resistant to many chemical solutions. They with stand fatigue excellently, do

not stress corrode and do not show any creep or relaxation, having less

relaxation compared to low relaxation high tensile prestressingsteel strands.

Carbon fiber is elastically conductive and there fore might give

galvanic corrosion in the direct contact with steel.

Figure 5.2. Carbon fiber reinforced sheets

5.3. ARAMID FIBER REINFORCED POLYMER

Aramid is the short form for aromatic polyamide. A well known

trademark of aramid fibres is Kevlar but there exists other brands too,e.g

Twaron, Technora and SVM.The modulli of the fibres are 70-200 GPa with ultimate

elongation of 1.5-5% depending on the quality.Aramid has a high fracture energy

and is therefore used for helmets and bullet-proof garments.Aramid fibres are

sensitive to elevated temperatures, moisture and ultraviolet radiation and

therefore not widely used in civil engineering applications.Further aramid

fibres do have problems with relaxation and stress corrosion.

6. FRP SHEETS AS EXTERNAL REINFORCEMENT IN RC BEAMS

The technique based on the externally bonded fiber reinforced

polymer (FRP) materials is one of the most widely used for retrofitting

existing damaged structures, since they have high mechanical properties in

lightweight, high strength, ease to install, and do not change significantly

the original geometry of the strengthened elements. The studies have shown that

the beams strengthened with FRP in flexural strengthening would avoid the

debonding failure mode when carefully designed anchorage is applied, which

gives good flexural performance in terms of strength and ductility.

6.1. FRP EBR SYSTEM

Different systems of

externally bonded FRP reinforcement exist, related to constituent materials,

the form and the technique of the FRP strengthening. In general, these can be subdivided

into “we lay-up” (or “cured in- situ”) systems and “prefab” (or “pre-cured”)

systems.

6.1.1. WET LAY-UP SYSTEMS

· Dry unidirectional fibre sheet and semi-unidirectional fabric

(woven or knitted), where fibers run predominantly in one direction partially

or fully covering the structural element. Installation on the concrete surface

requires saturating resin usually after a primer has been applied. Two

different processes can be used to apply the fabric:

Ø The fabric can be applied directly into the resin which has been applied uniformly onto the concrete surface,

Ø The fabric can be impregnated with the resin in a saturator machine and then applied wet to the sealed substrate.

· Dry multidirectional fabric (woven or knitted), where fibers run in at least two directions. Installation requires saturating resin. The fabric is applied using one of the two processes described above.

· Resin pre-impregnated uncured unidirectional sheet or fabric, where fibers run predominantly in one direction. Installation may be done with or without additional resin.

· Resin pre-impregnated uncured multidirectional sheet or fabric, where fibers run predominantly in two directions. Installation may be done with or without additional resin.

· Dry fibre tows (untwisted bundles of continuous fibers) that are wound or otherwise mechanically placed onto the concrete surface. Resin is applied to the fibre during winding.

· Pre-impregnated fibre tows that are wound or otherwise mechanically placed onto the concrete surface. Product installation may be executed with or without additional resin.

6.1.2. PREFABRICATED ELEMENTS

· Pre-manufactured cured straight strips, which are installed

through the use of adhesives. They are typically in the form of thin ribbon

strips or grids that may be delivered in a rolled coil. Normally strips are

Pultruded. In case they are laminated, also the term laminate instead of strip

may be used.

· Pre-manufactured cured shaped shells, jackets or angles, which are installed through the use of adhesives. They are typically factory-made curved or shaped elements or split shells that can be fitted around columns or other elements.

6.2. TECHNIQUES FOR FRP STRENGTHENING

6.2.1 BASIC TECHNIQUE

The basic FRP strengthening technique involves manual application

of either wet lay-up or fabricated systems by means of cold cured adhesive

bonding. Common in this technique is that the external reinforcement is bonded

onto the concrete surface with the fibers as parallel as practically possible

to the direction of principal tensile stresses.

Figure 6.1. Hand lay-up of CFRP sheets or fabrics

6.2.2. SPECIAL TECHNIQUE

Besides the basic techniques, several special techniques have been

developed. Some of them are a follows.

i. Automated wrapping: This technique was first developed in

Japan. This involves continuous winding of wet fibers under a slight angle

around columns or other structures.

ii. Prestressed FRP: In some cases it may be advantageous to bond

the external FRP reinforcement onto the concrete surface in a prestressed

state. Both laboratory and analytical research shows that prestressing

represents a significant contribution to the advancement of the FRP

strengthening technique, and methods have been developed to prestress the FRP

composites under real life condition.

iii. Fusion-bonded-pin-loaded straps: this technique involves

replacing solid and relatively thick strips known as pin- loaded strap.

iv. In-situ fast curing using heating devices: Instead of cold

curing of the bond interface (curing of the two-component adhesive under

environmental temperature), heating devices can be used. In this way it is

possible to reduce curing time, to allow bonding in regions where temperatures

are too low to allow cold curing, to apply the technique in winter time, to

work with prepreg FRP types, etc.

v. CFRP inside slits: CFRP in concrete slits is considered as a

special method of supplementing reinforcement to concrete structures. The slits

are cut into the concrete structure with a depth smaller than the concrete

cover. CFRP strips e.g. with a thickness of 2 mm and a width of 20mm are bonded

into these slits. vi. Prefabricated shapes: Prefab type of FRP EBR systems are

mostly applied in the form of straight strips. However, these can be produced

in other forms, depending upon their application. By shaping them, prefab

systems can be employed in applications where normally the more flexible wet

lay-up systems can be used. vii. FRP impregnation by vacuum: it is quite common

in the plastic industry. Vacuum impregnation is, to some extent, comparable

with wet lay-up. The concrete element to be strengthened according to this

method is pre-treated in the same manner as for the other method.

7. THE EXPERIMENTAL PROGRAM

7.1. GEOMETRY OF BEAMS AND TEST SET-UP

The experimental program is made of flexural tests carried out on

7 RC beams having width and length as 150mm, 1700mm and depth of 250mm or

300mm. the concrete cover thickness was 25 or 35 mm for the beam tested. Two

bars of diameter 8mm as internal steel reinforcement in compression, two 10 or

14 mm diameter bars as longitudinal reinforcement in tension. For the beams

tested, 6 mm diameter steel stirrups were placed along the entire length of the

beam with a spacing of 100 mm. For the 7 RC beams tested, one beam WR1 was kept

without retrofitting and considered as a reference beam. Rest 6 beams were

reinforced with either single layer or two layers of CFRP sheets. Here WR2 was

reinforced with one layer of CFRP sheets and WR3 with two layers of CFRP

sheets, without pre-crack. The other four beams, WR4, WR5, WR6 and WR7, were

pre-cracked with the maximum crack widths of 0.51, 0.59, 0.56 and 0.53 mm,

respectively, and subsequently strengthened with two layers of CFRP sheets.

Finally, two strips of the U-shaped CFRP sheets were bonded onto both sides of

the beam near the supports as external anchorage to reduce the edge stresses

and prevent the delamination of other CFRP sheets.

All the beams are simply supported over a clear span of 1500mm and

tested under four- point flexural load by using a servo controlled hydraulic

actuator having a maximum capacity of 200KN. The strain on concrete, steel, FRP

sheets of all beams is measure using instruments. In addition, three linear

voltage displacement transducers (LVDTs) were also used to measure deflections

at the mid-span and loading points.

7.2. MATERIAL USED

The yield strength (fy), ultimate strength (fu), elastic modulus

(E) and the ultimate elongation of the steel reinforcement and that of GFRP

sheets are shown in the table 7.1 below. Here the GFRP sheets of thickness

0.111mm are used.

Table 7.1.Mechanical properties of materials

7.3. FAILURE MODE AND LOADS

The failure mode of the reference beam WR1 is a typical bending

failure pattern. For the beams strengthened with one or two layers of CFRP

sheets, appearing of the cracks was delayed, also the width of those cracks and

the inter-space between cracks were reduced. There were two main failure modes

for the beams strengthened, i.e. snapping and debonding of CFRP sheets, and

shear cracks propagated toward the loading point accompanied by debonding of

the CFRP sheets from the concrete. The failure mode of the beams such as WR2,

WR3 and WR6 was characterized by the snapping of one layer or two layers of

CFRP sheets were bonded on the tensile side of beams. However, the beams of

WR4, WR5 and WR7 were failed by the debonding of CFRP sheets from mid span or

loading point. The table shows below summarizes the outcomes of the test

conducted:

Table 7.2. Test results of beam tested

7.4. LOAD-DEFLECTION BEHAVIOUR

Figure below shows that the initial stiffness of beams

strengthened increases significantly in comparison to the reference beam due to

the contribution from the CFRP reinforcement. The beam WR3 gives a smaller

deflection at the given load than that of beam WR4 from zero loads to the load

of 52KN, since the cracks developed during the preloading degraded the beams stiffness.

The beams with the higher longitudinal reinforcement ratio (WR5) or a deeper

cross section depth (WR6) may lead to a higher stiffness than that of the same

reinforcing beam (WR4) before the yielding of steel bars. However, the beam WR5

gives a higher stiffness but a lower ultimate strength than that of beam WR6,

this is due to the highest longitudinal reinforcement ratio contributed to

highest strength and the deepest cross-section depth lead to highest stiffness.

The stiffness of beams WR4 and WR7 which have the same reinforcement but

different concrete cover thickness is almost the same. The result indicated

that the concrete cover thickness may not be an influential factor to the

bending stiffness.

Figure 7.1. Load versus deflection curves for the beams tested

7.5. CRACKING BEHAVIOUR

During the test the maximum crack widths where measured at every

loading increment by the PTS-C10 crack width measuring device. The relationship

between the load and the corresponding crack width is shown in the table and

the figure below.

The strengthened beam gives a smaller crack width than that of

reference beam. This was due to the constraining effect of the attached CFRP

sheets on the strengthened beam. But during the initial loading up to

approximately 40 KN, the beams WR2 and WR3 shows a larger crack width than that

of reference beam, this might be caused by possible slipping and engaging

between FRP and concrete. The beam WR5, with the most longitudinal

reinforcement ratio and WR6 with the deepest cross-section depth gives a

smaller maximum crack width than that of beam WR3, WR4 and WR7. The result

shows that longitudinal reinforcement is more effective than the cross-section

depth and concrete cover thickness in controlling the crack development.

Figure 7.2.Load versus cracked width measured before the failure

Table 7.3. Data of cracks at failure for flexural beams tested

7.6. RESULTS OF THE EXPERIMENT

i. The ultimate load carrying capacity of all the strengthened beams

is higher when compared to the control beams.

ii. The initial cracks in strengthened beams are formed at higher

load compared to control beam.

iii. The flexural strengthening capacity of the beams strengthened

with externally bonded of CFRP increases significantly. The increase on overall

flexural capacity of CFRP strengthened beams varies between 41%nand 125% over

the reference beam. Hence applying FRP in the flexure zone is quite effective

method to enhance the load carrying capacity.

iv. The flexural strength could be diminished by increasing the

concrete cover thickness, but the deflection at mid span could be increased

greatly.

v. Both the ductility and strength for FRP strengthened beams

could be enhanced significantly by increasing the longitudinal reinforcement

ratio, but the preloading before the failure test might results in little

decrease in flexural strength, stiffness and ductility.

vi. Strengthening of continuous beam by providing U-wrap of FRP

sheets is a new and effective way of enhancing the load carrying capacity.

vii. Flexural failure at the intermediate support can be prevented

by the application of FRP sheets

8. APPLICATION OF FRP COMPOSITE IN CIVIL ENGINEERING

Over the last decade there has been significant growth in the use

of FRP composites as construction material in structural engineering. There are

three broad divisions in which applications of FRP in civil engineering can be

classified: repair and rehabilitation applications, application in construction

engineering and architecture, application in new constructions.

8.1. REPAIR AND REHABILITATION

Majority of repair and rehabilitation works consists of repair of

old deteriorating structures, damage due to seismic activities and other

natural hazards. Structural strengthening is also required because of

degradation problems which may arise from environmental exposure, inadequate

design, poor quality construction and a need to meet current design

requirement. Generally, FRP composites can be utilized for structural

rehabilitation in the following situations:

• Deficiencies at the design stage, including: design errors, inadequate factors of safety, use of inferior class materials and poor construction quality.

• Change of use, in service, namely, increased safety requirements (upgrading of structural design standards), modernization that causes redistribution of stresses and increase of the applied load.

• Ageing of materials that compromise the load capacity of the structure: for example concrete degradation in hostile marine or industrial environments.

• Accidents, as fire or seismic events.

8.1.1. REPAIR AND STRENGTHENING

Repair with FRP composites has been used successfully on concrete,

timber, metal and masonry structures. The predominant role of concrete as a

structural construction material simulated the application of FRP composite in

repairing of concrete structures such as bridges and large structural elements.

The basic FRP strengthening technique, which is most widely

applied, involves the manual application of either wet lay-up or prefabricated

systems by means of cold cured adhesive bonding. Common in this techniques is

that the external reinforcement is bonded onto the concrete surface with the

fibers as parallel as practically possible to the direction of principal

tensile stresses. Besides the basic techniques, several special techniques have

been developed, namely the automated wet lay-up wrapping of columns or

chimneys, use of pre-stresses FRP to close open cracks in bridge decks.

Near-surface mounted (NSM) technique may also be thought as a special method of

reinforcement of concrete structures. IN this method, grooves are first cut

into the concrete cover and the FRP reinforcement, usually a laminate strip, is

bonded therein with appropriate groove filler, typically epoxy paste or cement

grout.

8.1.2. SEISMIC RETROFIT

The problem of structural deficiency of existing constructions is

especially acute in seismic regions, as, even there, seismic design of

structures is relatively recent. The enhancement of confinement in structurally

deficient concrete columns in seismically active regions of the world has

proven to be one of the most significant applications of FRP materials in

infrastructure applications.

Seismic retrofit of reinforced concrete structures, namely

bridges, using conventional steel techniques has found to time consuming, it

cause significant traffic disruption, rely on field welding and is susceptible

to corrosion. Additionally, many of the method increases the stiffness and

strength capacity of the columns putting adjacent structural elements at risk

from higher transmitted seismic forces. The use of FRP composites in this

application, not only provides a means of confinement, without the associated

increase in stiffness, but also enables the rapid fabrication of cost effective

and durable jackets with little traffic interference.

Figure 8.1. Seismic retrofitting of column with FRP sheets

8.2. CONCRETE STRUCTURES REINFORCED WITH FIBER COMPOSITE

Concrete reinforced with fiber reinforced polymer (FRP) materials

has been

under investigation since the 1960’s. The predominant role of concrete as a construction material and the problems associated with corrosion of steel reinforcement stimulated the development of fiber composites for internal and external reinforcement of concrete and pre-stressing cables and tendons. Unstressed FRP reinforcement has been developed in a number of forms including ribbed FRP rod similar in appearance to deformed steel reinforcing bar, under formed E-glass and carbon fiber bar bound with polyester, vinyl ester or epoxy resin, E-glass mesh made from flat FRP bars and prefabricated reinforcing cages using flat bars and box sections. Stressed FRP reinforcement is also available, usually consisting of bundles of rods or strands of fiber-reinforced polymer running parallel to the axis of the tendon. These are used in a similar fashion to conventional steel tendons.

under investigation since the 1960’s. The predominant role of concrete as a construction material and the problems associated with corrosion of steel reinforcement stimulated the development of fiber composites for internal and external reinforcement of concrete and pre-stressing cables and tendons. Unstressed FRP reinforcement has been developed in a number of forms including ribbed FRP rod similar in appearance to deformed steel reinforcing bar, under formed E-glass and carbon fiber bar bound with polyester, vinyl ester or epoxy resin, E-glass mesh made from flat FRP bars and prefabricated reinforcing cages using flat bars and box sections. Stressed FRP reinforcement is also available, usually consisting of bundles of rods or strands of fiber-reinforced polymer running parallel to the axis of the tendon. These are used in a similar fashion to conventional steel tendons.

The durability of FRP composite is considered by engineers to

offer a possible solution to the problem of corrosion of steel reinforcement, a

primary factor in reduced durability of concrete structures. Other advantages

of FRP rebar include enhanced erection and handling speeds and suitability to

applications which are sensitive to materials which impede radio wave

propagation and disturb electromagnetic fields.

8.2.1 FRP BARS, RODS AND GRIDS

The use of FRP reinforcing bars and grids for concrete is a

growing segment of application of FRP composites in structural engineering. For

an effective reinforcing action, it is necessary to develop bond strength

between FRP and concrete. This is achieved in FRP rods by having various types

of deformation systems, including exterior wound fibers, sand coatings and

separately formed deformations. FRP reinforcing bars and grids for concrete

with both glass and carbon fibers are produced by a number of companies in USA,

Asia and Europe. Applications have become routine for certain specialized

environments, namely in bridge decks and in underground tunnels.

8.2.2 FRP CABLES FOR PRESTRESSING AND POSTSTRESSING APPLICATION

Composite cable applications in the infrastructure are used in the

construction of suspension and stay cables for bridges, pre-stressed tendons

for various concrete structures and external reinforcements for structural

beams. All these applications require materials that incorporate high tensile

strength and, in addition, require characteristics such as corrosion resistance

and light weight.

Corrosion of steel pre-stressing tendons can lead to the concrete

degradation and the deterioration of structural integrity. In cable-stay

applications, both corrosion and fatigue make the replacement of conventional

cables a significant life cost. FRP composites have good corrosion, durability

and fatigue characteristics and therefore the utilization of these materials

does make good engineering sense. The initial cost of this cables is higher

than other types of cables but this will nullify against their reduced

transportation cost, handling cost, maintenance cost etc.

FRP cables are unidirectional reinforced structural elements made

from glass, aramid or carbon fibers embedded in polymer matrix. Different

shapes such as bars, cables, rectangular strips and braided reinforcements are

available. Carbon fiber and aramid cables are used for pre-tension and post-

tension concrete, however glass fiber cables are not recommended for pre-

tension due to the low resistance to alkaline environments.

8.3 NEW FRP CIVIL STRUCTURES

A small number of new load bearing civil engineering structures

have been made predominantly from FRP materials over the last three decades. These

include compound curved roofs pedestrian and vehicle bridges decks energy

absorbing roadside guardrails(Bank and Gentry 2000), building systems, modular

rooftop cooling towers (Barbero and GangaRao 1991), access platforms for

industrial, chemical and offshore (Hale 1997), electricity transmission towers,

power poles, power pole cross-arms and light poles and marine structures such

as seawalls and fenders (Weaver 1999). FRP pultruded structures profiles have

been used in a significant number of structures to data, including pedestrian

bridges, vehicular bridges, building bridges, building frames, cooling towers,

walkways and platforms, etc. (Susana Cabral-Fonseca 2008).

9. ADVANTAGES AND DISADVANTAGES OF FRP COMPOSITE

9.1. ADVANTAGES

i. Low weight: The FRP is

much less dense and therefore lighter than the equivalent volume of steel. This

property of FRP makes its installation and handling significantly easier. Also

the use of FRP composite does not increase the weight of the structure or

dimensions of the member. And because of its light weight, the transport of FRP

material has minimal environmental impact.

ii. Mechanical strength: FRP can provide a maximum material

stiffness to density ratio of 3.5 to 5 times that of aluminum or steel. FRP is

so strong and stiff for its weight, it can perform better than other materials.

iii. Formability: The material can take up irregularities in the

shape of the concrete surface. It can be moulded to almost any desired shape.

We can create or copy most shapes with ease.

iv. Chemical resistance: FRP is minimally reactive, making it deal

as a protective covering for surfaces chemicals are present.

v. Corrosion resistance: Unlike metals, FRP does not rust away and

it can be used to make long- lasting structures.

vi. Low maintenance: Once FRP is installed, it requires minimal

maintenance. The materials fibers and resins are durable if correctly

specified, and require little maintenance. If they are damaged in service, it

is relatively simple to repair them, by adding an additional layer.

vii. Long life: it has high resistance to fatigue and has shown

excellent durability over the last 50 years.

viii. Easy to apply: The application of FRP plate or sheet

material is like applying wallpaper; once it has been rolled on carefully to

remove entrapped air and excess adhesive it may be left unsupported. Fibre

composite materials are available in very long lengths while steel plate is

generally limited to 6 m. These various factors in combination lead to a

significantly simpler and quicker strengthening process than when using steel

plate.

9.2. DISADVANTAGES

i. Low plastic behaviour

ii. High initial cost of the material

iii. Debonding failure may occur

iv. Susceptible to local unevenness.

v. Lack of accepted design standards.

10. CONCLUSION

The strength properties of FRP composite are the major reason for

which it is used in the design of structures by civil engineers. The strength

of a material depends on its ability to sustain the loads without excessive

deformation or failure. When the specimens reinforced externally with FRP

sheets is tested in axial tensions, the applied force per unit cross-sectional

area(stress) is proportional to the ratio of change in specimen’s length to its

original length(strain). When the load applied is removed, the FRP returns to

its original shape or length. In other words, FRP responds linear – elastically

to the applied axial stress. The response of FRP to axial compression is

reliant on the relative proportion in volume of fibres, the properties of fibre

and resin, and the interface bond strength. The compression failure in FRP

occurs when the fibres exhibit extreme lateral or side way deflection called

fibre buckling. FRP’s responds to transverse tensile stress is very much

dependent on the properties of fibre and matrix, the interaction between the

fibre and matrix, and the strength of fibre matrix interface. But the tensile

strength is very poor in this direction.

Shear stress is included in the plane of an area when external

loads tend to cause two segments of a body to slide over the other. The shear

strength of the FRP composite is difficult to quantify. The failure will

generally occur within the matrix material and is parallel to the fibres. FRP

composite have high strength properties and also have the most relevant

features which includes excellent durability and corrosion resistant. Also,

their high strength to weight ratio is of significant benefit; a member

composed of FRP can support larger live loads since its dead weight does not

contribute significantly to the loads that it must bear. Other features includes

ease of installation, versatility, anti-seismic behaviour, electromagnetic

neutrality, excellent fatigue behaviour and fire resistance. FRPs also have a

few drawbacks such as high cost, brittle behaviour, susceptibility to

deformation under long term loads, UV degradation, photo degradation,

temperature and moisture effects, lack of design codes, and most importantly

lack of awareness.

REFERENCE

1. Jiangfeng Dong et al (2011), CFRP sheets

for Flexural Strengthening of RC Beams, IEEE for Civil Engineering,

Page-1000-1003.

2. C. D. Modhera & Kaushal Parikh (2012), Application of

GFRP on preloaded retrofitted beam for enhancement in flexural strength, International

Journal of

Civil and Structural Engineering, Volume 2, No 4, Pages-1070-1080.

Civil and Structural Engineering, Volume 2, No 4, Pages-1070-1080.

3. E. Rakesh Reddy(2014), Strengthening Of RC Beam Using

FRP Sheet,

International Journal of Modern Engineering Research (IJMER), Volume 4, Issue.7, Pages-30-62.

International Journal of Modern Engineering Research (IJMER), Volume 4, Issue.7, Pages-30-62.

4. J.G. Dai et al (2005), Flexural strengthening of

RC beams using externally bonded FRP sheets through flexible adhesive bonding, Proceedings

of the

International Symposium on Bond Behaviour of FRP in Structures (BBFS 2005), Page 205-214.

International Symposium on Bond Behaviour of FRP in Structures (BBFS 2005), Page 205-214.

No comments:

Post a Comment